We are super excited to announce that we will be expanding on the line of workshop solutions we offer to bicycle workshops across Southern Africa by adding Sapim Spokes to our line-up of brands.

Founded in 1918 by Mr. Herman Schoonhoven, Sapim has been producing spokes and nipples of the highest quality for over a century!

Sapim would not have survived over 100 years if it didn’t rely on the best and most motivated people. They are a team of professionals dedicated to bicycle spokes and nipples. Everybody is committed to providing top-notch expertise, experience and advice to customers, much the same as we do at Rush Sports.

At Sapim, customer has always been central to their our activities. From the beginning, Sapim has strived to maintain a close relationship with its customers. Like Rush Sports, Sapim realise that it is important to place the customer at the centre of the "wheel" so to speak, and this makes a massive difference. We have noticed immediately from our early interaction with them just how much they are open to new ideas, and listen to the needs and wishes of their partners, in this case, Rush Sports, and through this collaboration we are confident we can provide the very best solution for EVERY bicycle workshop in South Africa, and every consumer, whether professional or amateur.

Sapim offer a wide range of products made from the very best raw materials only. They often call on the services of a unique testing facility to test the performance of their products and those of their competitors, because wheels are subject to more and more intensive uses, higher pressures and stronger weight requirements. Today many professionals rely on Sapim products, Santa Cruz / Reserve Wheels are a prime example as these are build exclusively with Sapim spokes, so it is without surprise that Sapim is considered by many professionals as the leader in the design and production of spokes and nipple.

For those "tech junkies" out there, take a read through the history and features below:

Timeline

|

Foundation by Mr Herman Schoonhoven of Sapim (Société Anonyme Pour l’Industrie des Métaux), a company specializing in the production of spokes and nipples |

1918 | |

|

1946 |

Company taken over by the son-in-law of the founder, Mr Florent Lambrechts |

|

|

Development of the Polyax nipple |

1995 |

|

|

1997 |

Development of the CX Ray spokes |

|

|

Start of Sapim USA |

2001 |

|

|

2004 |

Start of Sapim Asia |

|

|

Acquisition of France Rayon that later became Sapim France |

2005 |

|

|

2009 |

Launch of the D-Light spokes |

|

|

Launch of the Super spokes |

2010 |

|

|

2011 |

Acquisition of Ryde International by the Shareholders of Sapim |

|

|

Start of Sapim Hungary |

2013 |

|

|

2014 |

Start of production in Taiwan |

|

|

Move to new headquarter |

2015 |

|

|

2016 |

Development of the E-bike spokes |

|

|

100 year milestone |

2018 |

|

| 2020 |

Closing of the facilities of Sapim in France and Hungary and move all machines to the Corporate HQ in Belgium

|

|

| Opening a new facility in Belgium to allow the growth of the production at the HQ facility in Belgium | 2020 |

What is a bicycle spoke?

What is a spoke? You can define it in different ways: a piece of steel, a wire, a spring or, what we like best, the connection between the hub and the rim. Being the link between the hub and the rim, the spoke has multiple functions:

- Carry: spokes carry the weight of the bicycle as well as it load.

- Absorb: spokes absorb the irregularities of the road and ensure the comfort of the rider.

- Transmission: spokes transmit acceleration and braking effort of the rider.

When you see professional riders coming downhill at close to 90 km/h on their bike, you realize the vital importance to get the best quality of spokes and nipples.

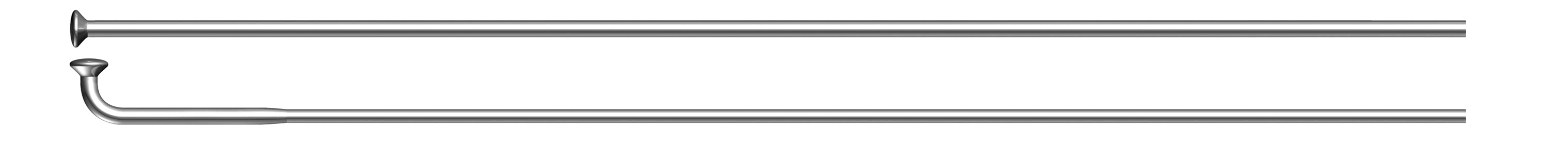

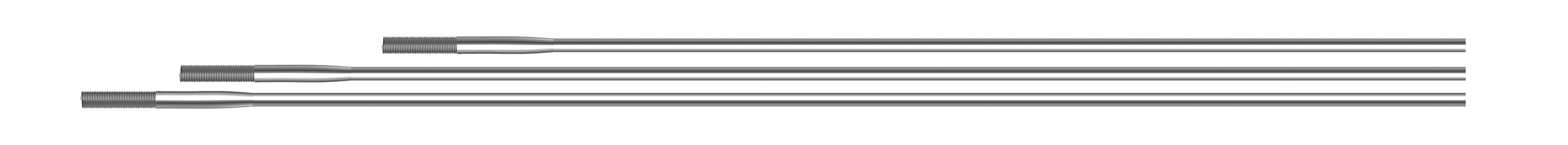

We use different grade of steel, different diameters, heads, surfaces and, of course, length. Producing with care and on highest quality standards we offer the widest range in the market. All our spokes are produced in Sapim facility located in Europe and in Asia. In every production location we implemented an identical and strict quality control processes.

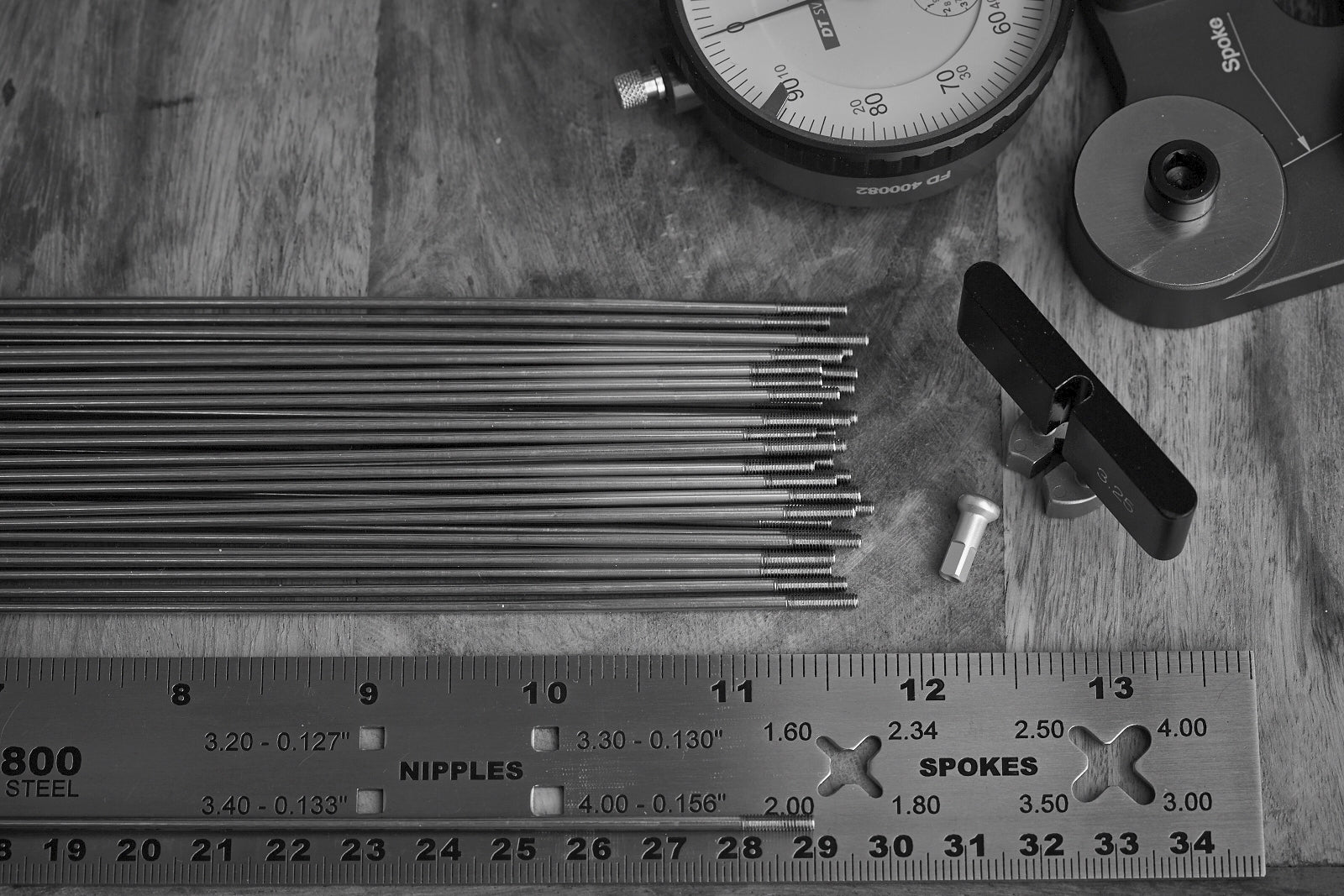

Head with bending

Our standard spokes have a bending length of 2,8 mm. This is optimal for at least 90% of the hubs in the market.

But sometimes the standard bendings

are wrong. Steel hubs need shorter bend. You can adjust this with our spoke washer (see page 34 for more details).

Material

Sapim uses only high grade stainless steel specially drawn to our own specification of material and tensile strength. The long term experience and many trials insure that Sapim spokes last long.

Precise definition and small tolerances are constant point of attention in the production process. This guarantees the highest quality for millions of spokes Sapim produces every year.

Thread

Spoke thread is rolled and not cut. Rolling the thread improve the strength. The name of the thread on a standard 2mm spoke is called FG 2,3 mm.

Options

The world of wheel building and the demand of the market can make spoke different to the standard. For some we have to add anti rotation parts, hammer head, torsion control squares (picture), colors (picture) or different bending length to the spokes (picture). Also a lot more different spoke models are available only for manufacturers. Our variety ensures that you can build up wheels with nearly all available rims and hubs and can repair all standard wheels. For repairs of special branded wheels you should contact your local distributor.

Straight and bending

Silver and black

Torsion control squares

Many different lengths

Surface treatment

Black oxidation is a chemical process that transfers the first few microns of the stainless steel surface into a black layer. This method has the advantage of being done in a bulk process, which has a positive effect on the price and capacity (availability and delivery time). This process is performed by high quality minded companies specially selected by Sapim to achieve the highest quality possible.